Accurate AFM Solutions for FA and Research Laboratories

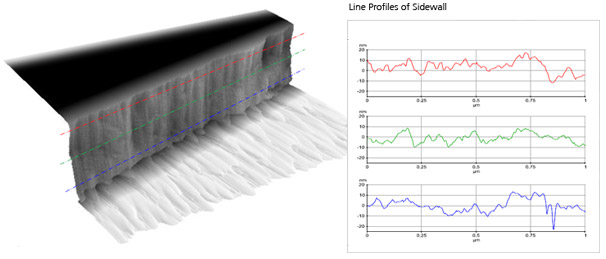

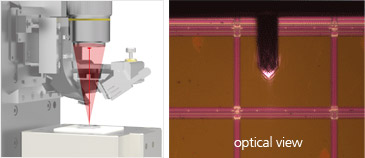

Sidewall measurements for 3D structure study

The NX20’s innovative architecture lets you detect the sidewall and surface of the sample, and measure their angle. This gives the unit the versatility you need to do more innovative research and gain deeper insights.

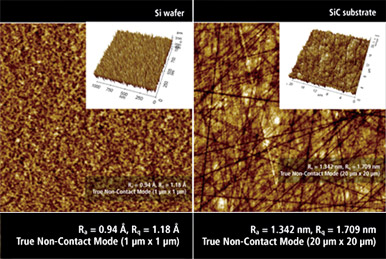

Surface roughness measurements for media and substrates

Read More related application

High resolution electrical scan mode

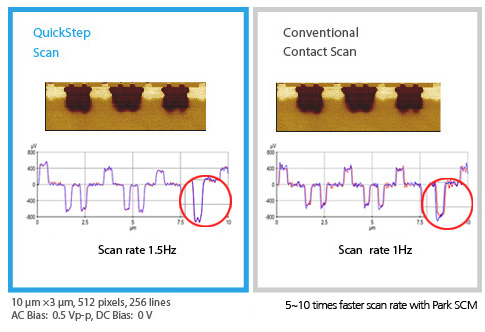

QuickStep SCM

The Fastest Scanning Capacitance Microscopy

PinPoint AFM

The Frictionless Conductive AFM

Accurate and Reproducible Measurements for Better Productivity

Tip lifetime performance data on polished silicon wafer: 15,000 scans @ 10Hz using 1 tip!

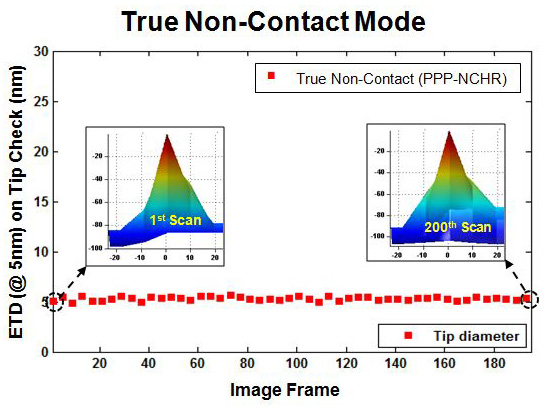

Reproduce Best AFM Measurement

True Non-Contact Mode preserves the sharp tip end even after imaging 200 images of CrN, so called tip check sample. CrN has very abrasive surface that may quickly wear out the sharp tip.

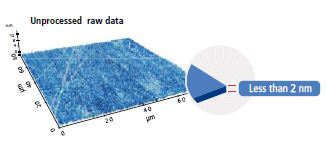

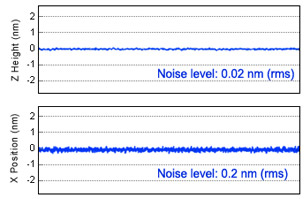

Accurate AFM Topography with Low Noise Z Detector

True Sample Topography™ without piezo creep error

Our AFMs are equipped with the most effective low noise Z detectors in the field, with a noise of .02 nm over large bandwidth. This produces highly accurate sample topography, no edge overshoot and no need for calibration. Just one of the many ways Park AFM saves your time and gives you better data.

- Low noise Z detector signal is used for topography

- Low Z detector noise of 0.02 nm over large bandwidth

- No edge overshoot at the leading and trailing edges

- Calibration needs to be done only once at the factory

Park NX AFM

Conventional AFM

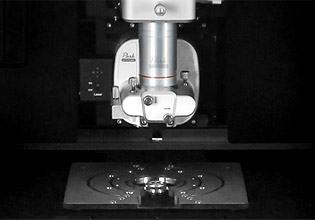

Park NX20 features

The XY

scanner consists of symmetrical 2-dimensional flexure and high-force piezoelectric stacks provides high

orthogonal movement with minimal out-of-plane motion as well as high responsiveness essential for precise sample

scanning in the nanometer scale.

The XY

scanner consists of symmetrical 2-dimensional flexure and high-force piezoelectric stacks provides high

orthogonal movement with minimal out-of-plane motion as well as high responsiveness essential for precise sample

scanning in the nanometer scale.

The industry leading low noise Z detector replaces the applied Z voltage as the topography signal. In addition, the low noise XY closed loop scan minimizes the forward and backward scan gap to be less than 0.15% of the scan range.

Using the motorized sample stage, Step-and-Scan enables user-programmable multiple region imaging. The Step-and-Scan process consists of:

1) Scan an image

2) Lift the cantilever

3) Move the motorized stage to a user defined coordinate

4)

Approach

5) Repeat the scan

This automated feature increases productivity by minimizing user assistance during repetitive imaging processes.

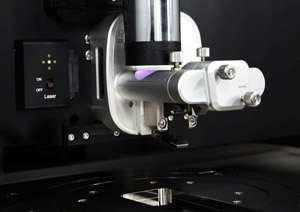

The AFM head is easily inserted or removed by sliding it along a dovetail rail. This automatically locks the head into its pre-aligned position and connects it to the control electronics with a positioning repeatability of a few microns. The low coherency of the Super Luminescence Diode (SLD) enables accurate imaging of highly reflective surfaces and precise measurements for pico-Newton Force-distance spectroscopy. The SLD wavelength eliminates interference issues for users interested in combining the AFM with experiments in the visible spectrum.

Advanced SPM modes are enabled by simply plugging an option module to the expansion slot. The modular design of the NX-series AFM allows option compatibility throughout its product line.

All NX-series AFMs are controlled and processed by the same NX electronics controller. The controller is an all digital, 24-bit high speed electronics unit, which insures the speed and accuracy of Park’s True Non-Contact ModeTM for accuracy and speed. With its low noise design and high speed processing unit, the controller is ideal for nanoscale imaging and precise voltage and current measurements. The embedded digital signal processing capability adds to the functionality and economics of our AFM solutions for advanced researchers.

24-bit signal resolution for XY and Z detectors

• 0.003 nm resolution in XY (50 μm XY)

•

0.001 nm resolution in Z (15 μm Z)

Embedded digital signal processing capability

• 3 channels of flexible digital lock-ins •

Spring constant calibration (thermal method)

• Digital Q control included

Intergrated signal access ports

• Dedicated and programmable signal input/output ports

•

7 inputs and 3 outputs

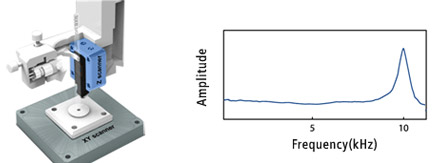

Driven by a high-force piezoelectric stack and guided by a flexure structure, the standard Z scanner has a high resonant frequency of more than 9 kHz (typically 10.5 kHz), and Z-servo speed of more than 48 mm/sec tip velocity which enables accurate feedback. The maximum Z scan range can be extended from 15µm to 30µm with the optional long scan range Z scanner.

The encoders, used on all motorized stages, enable higher positioning repeatability for accurate sample positioning. The encoded XY stage travels in 1 µm resolution with 2 µm repeatability, and the encoded Z stage, in 0.1 μm resolution with 1 μm repeatability.

The unique head design allows for an open side access to sample and tip. The maximum sample size one can place on the stage is either 150 mm diameter x 20 mm or 200 mm diameter x 20 mm depending on the travel range option chosen for the XY sample stage.

Custom designed objective lens with ultra long working distance (51 mm, 0.21 NA, 1.0 µm resolution) provides direction on-axis optical view with unprecedented clarity. The intuitive direct on-axis sample view from the top allows users to navigate the sample surface easily to find the target area. For a higher vision resolution the EL20x objective lens of Long Travel Head is used, which has 20 mm working distance, 0.42 NA, and 0.7 µm resolution. The enlarged sensor size of the CCD provides wide field of view of the sample without compromising the optics resolution. The software-controlled LED light source provides ample illumination onto the sample surface for clear sample observation.

The Z stage and focus stage engage the cantilever with the sample surface while constantly maintaining a clear field of vision for the user. And because the focus stage is motorized and software controlled, it has the precision necessary for transparent samples and liquid cell applications.